News

Introduction of a New Production Technology of Extruded Food

Introduction of a New Production Technology of Extruded Food.

3D puffed food is a new kind of puffed food which has just appeared in China in recent years.

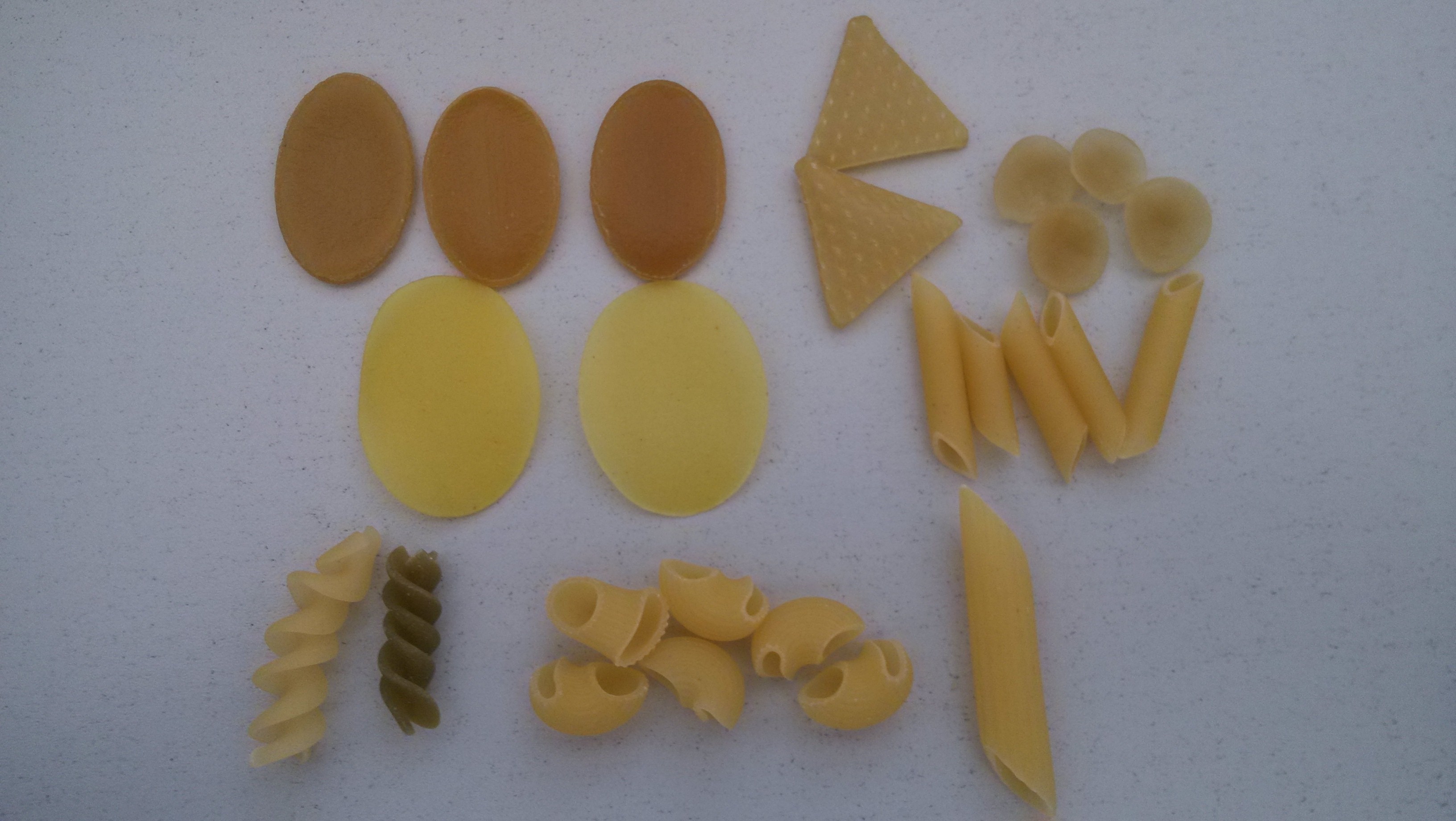

Different raw materials can be divided into potato three-dimensional puffed food and cereal three-dimensional puffed food. Especially cereal three-dimensional puffed food has more market advantages because of its low cost. The appearance of three-dimensional puffed food does not follow the stereotype, instead of the traditional puffed food flat and lack of change of a single pattern, the use of a new production technology, so that the product produced has a variety of shapes, a strong three-dimensional sense, and delicate organization, crisp taste, but also can be made into various animal shapes and interesting crisp corners, network crisp, pillow packs, etc., so it will be used as soon as it comes into the world. Novelty appearance and peculiar taste are favored by consumers.

The production process produced by Jinan AVAN Machinery Co., Ltd.

corn starch, rice starch, potato starch.

2. Process flow:

batching, mixing pretreatment extrusion cooling composite forming drying frying seasoning and packaging.

3. Process analysis:

3.1 Mixing

The process of mixing is to mix dry materials evenly and mix water to achieve pre-wetting effect. This process has a great influence on the final product forming effect. In general, the moisture content of the material after mixing is 28%-35%, which is completed by the mixer.

3.2 Pre condition

The pretreated raw materials are cured by spiral extrusion to 90%-100%. It is prepared for the next extrusion process. This process is controlled by a special spiral design and an effective thermostat. Generally, the setting temperature is 100-120 C and the medium pressure is 2-3 atmospheric pressures.

3.3 Extrusion.

Extrusion is the key process of the process. Material matured automatically enters the low shear extrusion screw, and the temperature is controlled at 70-80 C. After special die, large sheets with width of 200 mm and thickness of 0.8-1 mm are extruded, which are translucent and have good toughness. Its thickness directly affects the composite forming and drying time, so the die must be equipped with a device to adjust the pressure balance to control the uniform discharge.

3.4 Cooling system.

The cooling length of the extruded sheet must be 8-12 m, which can effectively ensure the demoulding of the compound machine during product forming. In order to save space, the cooling device can be designed as up-and-down cycle traction to ensure the cooling length of at least 10 m.

3.5 Composite Forming.

The process is completed by three groups of programs. The first step is embossing: two groups of embossing rollers operate to make the surface of the sheet material mesh and play the role of traction. Animal shapes or other sheet materials that do not require a surface mesh can be replaced by flat rollers to provide traction only. The second step is compounding: after embossing, the two pieces are guided and overlapped into the composite roll, the finished products are dried with the conveyor belt, and the surplus materials are put into the third step recovery device, which is completed by a group of conveyors specially returned to the extruder, so as to re-enter the extrusion process and ensure the uninterrupted production.

3.6 Drying.

The moisture content of the extruded snacks is between 20% and 30%, and the moisture content of the snacks is 12% before the next process. Because these snacks have formed a dense structure at this time, they can not be dried quickly, which requires a longer time to dry under the condition of the temperature of the previous process (usually 60 C), in order to keep the shape of the product stable. In addition, in order to prevent the composite billets from adhering to each other, it is better to install micro-vibration device to make the products independent after drying.

3.7 Frying or baking.

After frying and drying, the snacks enters the frying pan to finish cooking and remove moisture, so that the final moisture of the product reaches 2%-3%. The billet expands by 2-3 times due to the rapid evaporation of its moisture, and is in three-dimensional shape. Then the greasy feeling can be removed by throwing oil and the final process can be carried out.

3.8 Seasoning and packing.

The process of seasoning and packaging can be finished by spraying powder seasoning on the surface of products according to the taste of consumers, using automatic drum seasoning machine and powder spraying machine or octagonal seasoning machine.