Mcdonalds chicken nugget machine

Chicken nugget machine is a piece of food processing equipment designed specifically for the production of chicken nuggets. These machines are part of the broader category of food processing equipment used in the poultry and fast-food industries.

The processing of the nuggets.

Processing and Mixing:

Raw chicken meat is usually processed and ground to achieve the desired texture for chicken nuggets.

Ingredients such as seasonings, binders, and fillers are added to the chicken mixture for flavor and consistency.

Forming:

The mixture is then shaped into nugget forms. This can be done using molds or extrusion equipment.

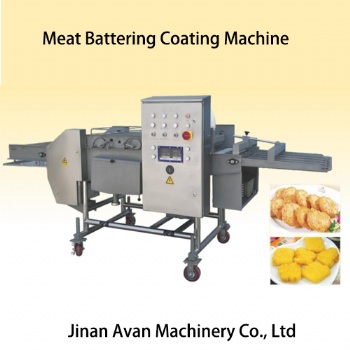

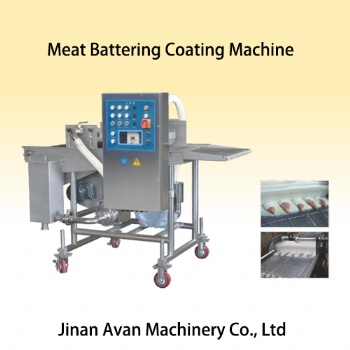

Battering and Breading:

The formed chicken nuggets are often passed through a battering station where they are coated with a batter to provide a crispy outer layer.

Next, the battered nuggets may be coated with breadcrumbs or another type of breading.

Frying:

The breaded nuggets are then usually deep-fried until they reach the desired level of crispiness and are fully cooked.

Quality Control:

Throughout the process, there are likely quality control measures in place to ensure the consistency and safety of the product.

Packaging:

Once cooked and inspected, the chicken nuggets are typically packaged for distribution to various outlets

Nugget machine capacity.

The AVN 200 machine capacity, 100 kg per hour.

The AVN 300 machine capacity, 200 kg per hour.

The AVN 400 machine capacity, 400 kg per hour.

Invest in the Commercial McDonald's Type Chicken Nugget Machine to enhance the efficiency and output of your commercial kitchen. Deliver the same high-quality, delicious chicken nuggets that customers love from the iconic fast-food chain and take your business to new heights of success.

Inquiry us to get machine price on chicken nuggets production line.