Hot Sale Animal Feed Equipment

Animal Feed Equipment Introduction

Animal Feed Equipment Materials

Animal Feed Equipment Making Process

Animal Feed Equipment Capacity

Animal Feed Equipment Features

Animal Feed Equipment Introduction.

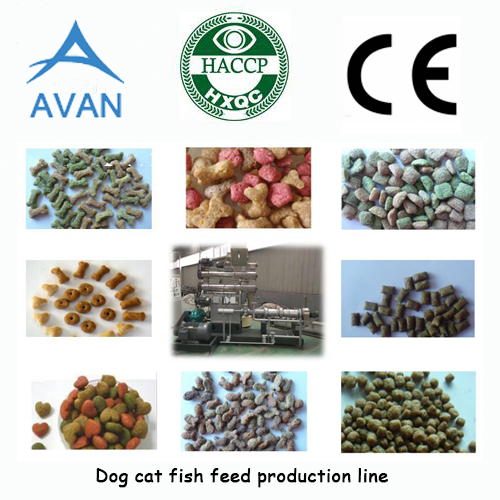

The animal feed equipment is used to produce the dog food, cat food, fish feed, bird feed, and so on. As the extruder machine could produce different shape products with different moulds, so the animal feed machine is well saled all over the world.

The animal feed equipment line includes machines as follows:

Mixer machine, Screw conveyor, Extruder machine, Air conveyor/ belt conveyor, Dryer machine, Belt conveyor, Drum flavoring machine, oil sprayer, packing machine.

Animal Feed Equipment Materials

The raw materials for animal feed.

1. Corn meal, bone meal, fish meal, soybean cake meal, bran, sweet potato meal, salt, auxin, calcium hydrogen phosphate, water ect.

These are materials for mixing together. And extruder machine will cook and shape materials into products.

2. The animal oil and plant oil, seasoning powder. They are used to spray and seasoning products.

The energy used for machines.

1. Machines adopt electricity energy.

2. There is a pre conditioner machine, which use electricity and steam energy. It is used to pre cook materials before extruder machine.

3. The dryer machine use the electricity energy. The heating could be gas, diesel, steam, electricity.

Animal Feed Equipment Making Process.

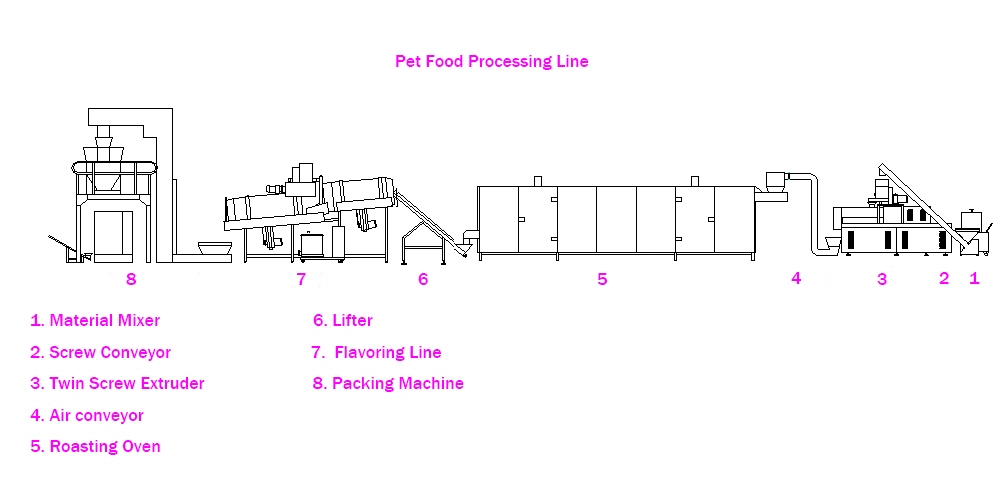

The mixer machine

It is used to mixing all materials together with water.

Power: 4kw.

Batch type working.

One batch 5-8 mins.

The pre conditioner machine on extruder machine.

Preconditioner machine is used to pre-cook the materials to make good quality animal feed. This machine needs steam energy.

The double screw extruder machine

The double screw extruder machine is main machines on animal feed processing. The screw and barrel give materials high pressure and high temperature. Materials is cooked well. The moulds are designed to produce different shape products with one extruder.

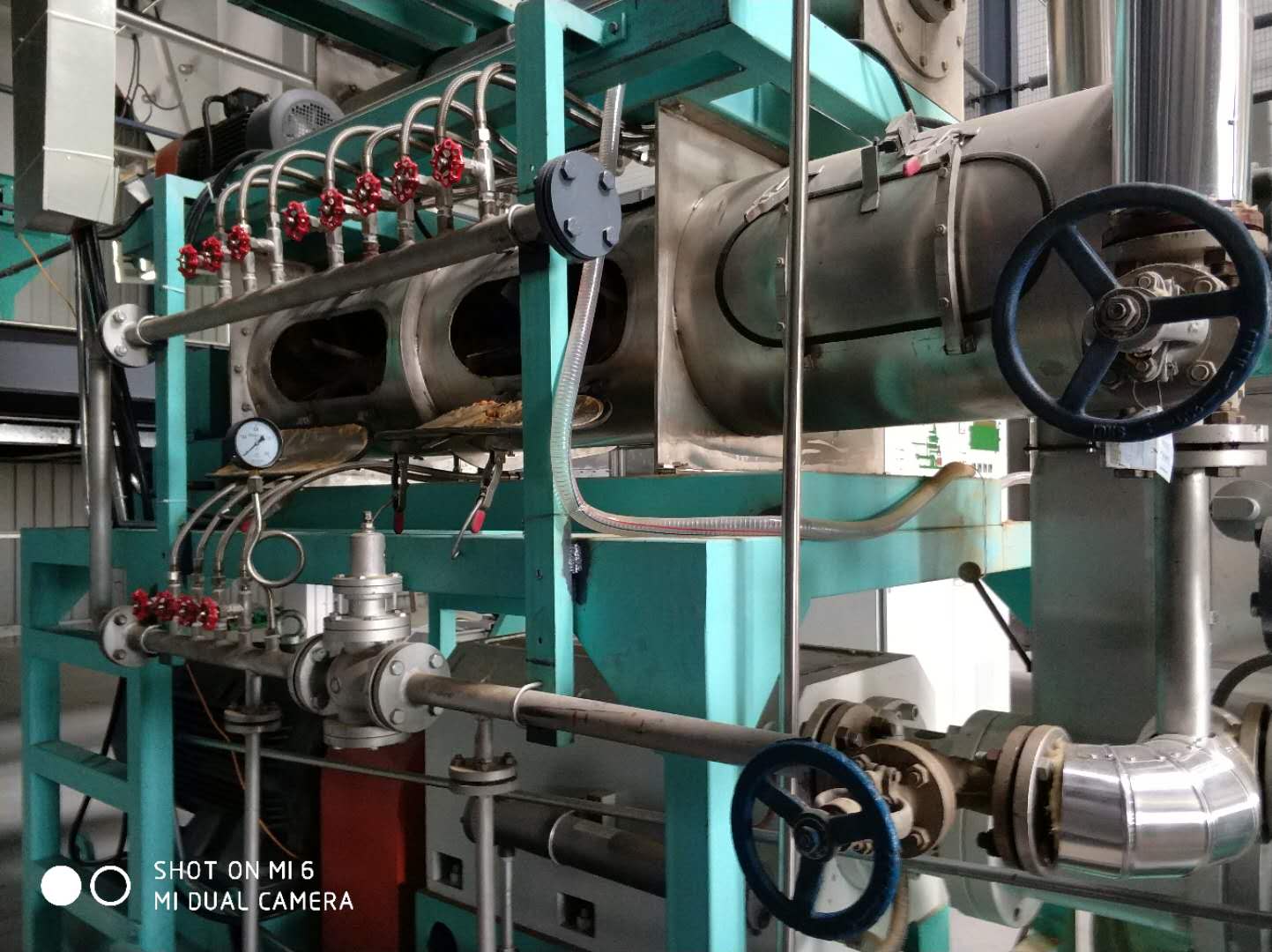

The dryer machine for aninal feeds.

Dryer machine is necessary, as the extruder machine producing needs water inside raw materials. Moisture content is about 25%. The dryer machine will make dehydrating to 8-10% before flavoring and packing.

Animal Feed Equipment Capacity.

| Model | AVN65 | AVN70 | AVN75 | AVN85 | AVN95 | AVN100 | AVN120 |

| Screw Dia' | 65MM | 70MM | 72MM | 80MM | 92MM | 100MM | 120MM |

| Screw Length | 1140MM | 1410MM | 2100MM | 1850MM | 2200MM | 2500MM | 2700MM |

| Number of screw | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Main Motor | 22KW | 37KW | 55KW | 75KW | 110KW | 150KW | 180KW |

| Heater | 15KW | 15KW | 18KW | 20KW | 24KW | 30KW | 30KW |

| Capacity | 150KG/H | 200KG/H | 300KG/H | 500KG/H | 1200KG/H | 2000KG/H | 4000KG/H |

| Weight | 1200KG | 1500KG | 2100KG | 2500KG | 2800KG | 3000KG | 3200KG |

Dimension | 3500*1100* 1850MM | 3500*1100* 2000MM | 5000*1200* 2000MM | 4300*1200* 2000MM | 5000*1200* 3500MM | 7100*1200* 3500MM | 7800*1200* 3500MM |

Animal Feed Equipment Features.

1.Materials are stainless steel on food contacting. Machine frame is carbon steel.

Screw material is 38CrMOAl. Tempering HB220—270. Nitriding HRC> 65.

2. Animal feed equipment is easy to operate. It needs 3-4 labours on whole machine lines.

3. Animal feed equipment is multi-function. Different diameter products, and different shape products could be produced with one machine line.

4. Our engineer is available oversea to install machines and teach machine operating.

5. We supply the basic formula on different products.

Animal Feed Equipment Video.