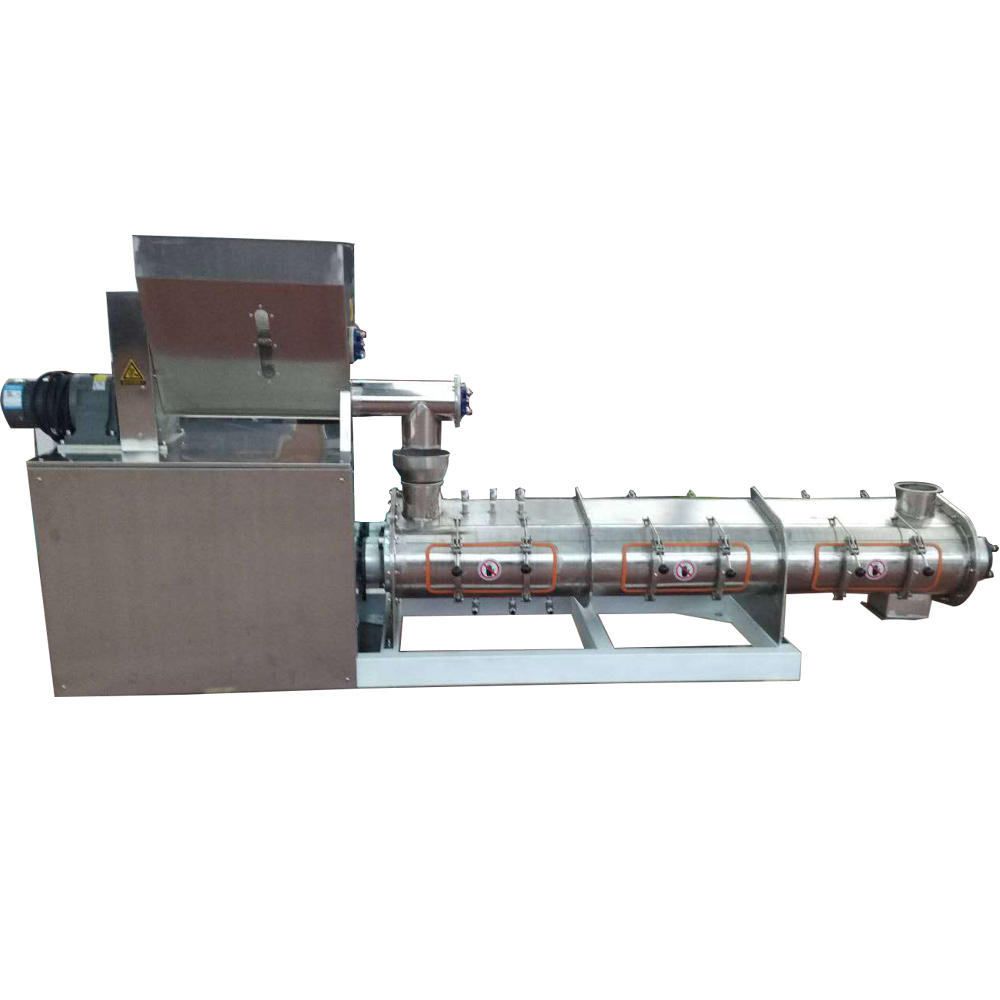

Pre-conditioner machine

The pre conditioner machine is used to pre handle materials before twin screw extruder machine, used to snacks food, fish feed, pet food and other products, to improve the products quality.

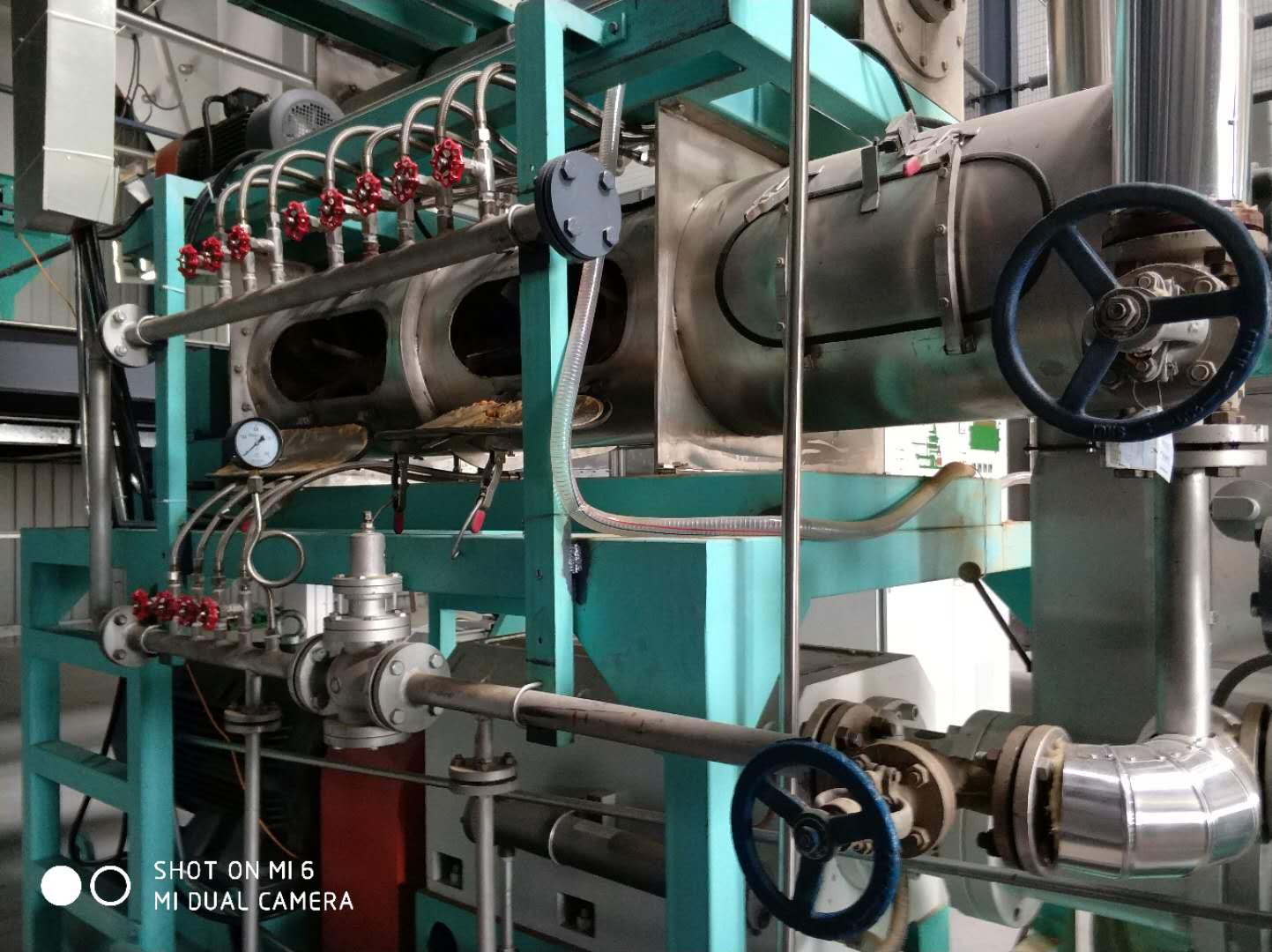

The conditioner is suitable for the production of aquatic materials and high-grade livestock and poultry materials. The machine is equipped with a dual-shaft differential conditioner, which uses multi-point steam inlet, long tempering time, sufficient tempering, high maturity, and different shaft diameters. Different speeds and different rotations in opposite rotation directions allow materials, steam, and liquid to be fully sheared and mixed under the stirring of two-axis paddle blades.

All the material contact parts in the preconditioner are made of stainless steel, and the conditioner uses a large door structure, which is easy to operate and maintain. The blade angle can be adjusted to control the time for tempering. Granulation of small particles. The conditioner is mainly composed of paddles or augers and nozzles. Usually steamor water is sprayed into the conditioner. The longer the time, the better.

The conditioner is mainly composed of paddles or augers and nozzles. Usually steam is sprayed into the conditioner to make the material evenly mix and soften with the additives in the conditioner. Well, the tempering time of general livestock and poultry feed is about 20 seconds. During this period, the powdered feed absorbs heat and moisture in the water vapor, softens itself, and facilitates pellet formation. For special animals and aquatic feed, in order to improve its quality and water resistance, it is generally necessary to extend the conditioning time.

Machine specification.

| Name | Voltage | Augers | Capacity | Steam | Dimension | Speed |

| Conditioner machine | 380V 50Hz | Double | 300-2000kg per hour | 0.1 ton 0.1Mpa | 1800*500*1200mm | Differential speed |

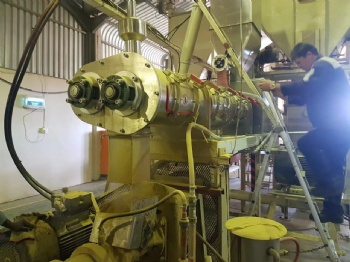

Conditoner machine is used on extruder, pellet machines and so on, for feed processing machines.